Xitoy filament uchun sof nikel simli Ni200 sim ishlab chiqaradi

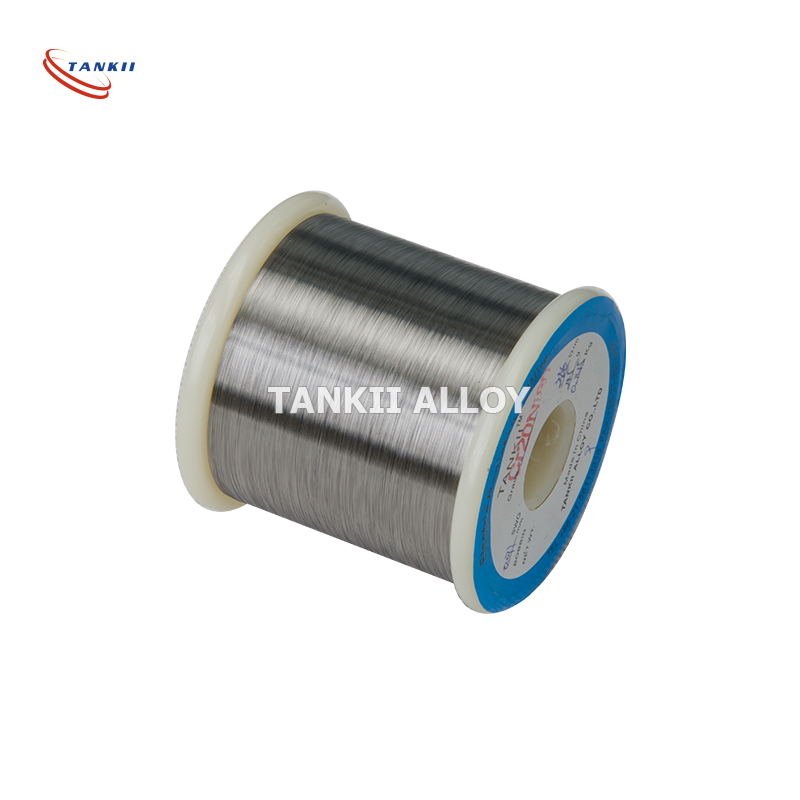

Xitoyda ishlab chiqarilgan sofNikel simFilament uchun Ni200 sim

Shanxay TANKII Alloy Material Co., Ltd. Nichrom qotishmasi, termojuft simi, FeCrAl qotishmasi, aniq qotishma, mis ishlab chiqarishga ixtisoslashgan.NikelQotishma, termal purkagich qotishmasi va boshqalar sim, varaq, lenta, tasma, novda va plastinka shaklida.

SofNikel Sim

1.> Yuqori harorat sharoitida yaxshiroq mustahkamlik va past qarshilik xususiyatlariga ega.

2.> Harorat: yumshoq; qattiq; 1/2 qattiq

3.> Ishlab chiqarish aylanishi: 3-7 kun

4.> Seriyalarsof nikel sim: nikel 200 sim, nikel 201 sim.

5.> Soflik 99.99% gacha, juda yupqa esa 0.02 mm gacha yetishi mumkin

Xususiyatlari

1.> Lehimlash qobiliyati, yuqori o'tkazuvchanlik, mos chiziqli kengayish koeffitsienti bilan

2.> Yuqori haroratda yaxshiroq kuch, past qarshilik

3.> Yuqori erish nuqtasi, korroziyaga chidamliligi, yaxshi mexanik xususiyatlari, issiq va sovuq holatda yaxshiroq bosimli ishlov berishga ega, gazni oson tozalash, radio, elektr yorug'ligi, mashinasozlik, kimyo sanoati, vakuumli elektron qurilmalar uchun muhim tarkibiy materialdir.

Sof nikel simining kimyoviy tarkibi:

| Nikel darajasi | Ni+Co | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | 99.0 | .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | 99.0 | .25 | .3 | .35 | .15 | .2 | .01 | .3 | - |

![]()

![]()

![]()

![]()

Bizning xizmatimiz:

1.> Biz sinov uchun bepul namunani taqdim eta olamiz, ammo yuk sizniki.

2.> Agar kerak bo'lsa, tegirmon sinov sertifikati ishlab chiqarilgandan so'ng taqdim etiladi.

3.> Yetkazib berish paytida tovarlarga zarar yetkazmaslik uchun yaxshi qadoqlash usullari

4.> Biz ko'plab mashhur ekspeditorlar bilan hamkorlik qilamiz, mijozlarimiz uchun xavfsiz, qulay, tezkor va arzon transport turini tanlashga harakat qilamiz.

Bizning boshqa seriyamizelektr isitish simi

| Qotishma turi | Diametri (mm) | Qarshilik (μΩm)(20°C) | Cho'zilish Kuch (N/mm²) | Uzayish (%) | Bükme Times | Maks. Davomiy Xizmat Harorat (°C) | Ish hayoti (soat) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350-yil | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

![]()

![]()

![]()

![]()

Mahsulotlar toifalari

-

Telefon

-

Elektron pochta

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Yuqori