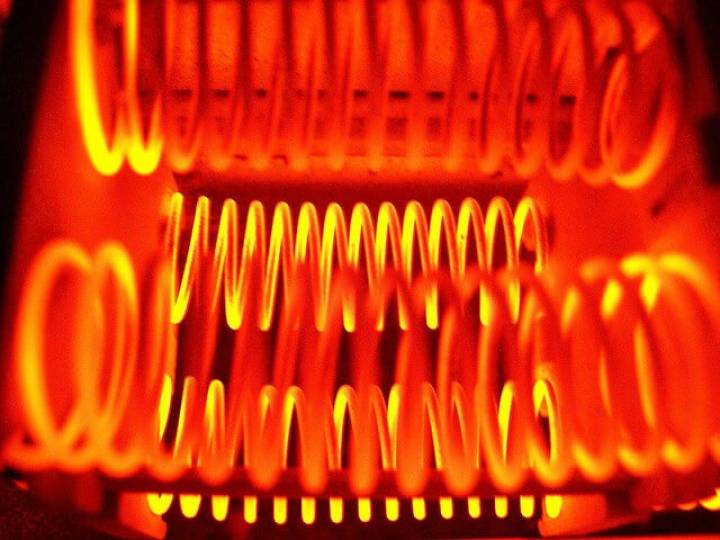

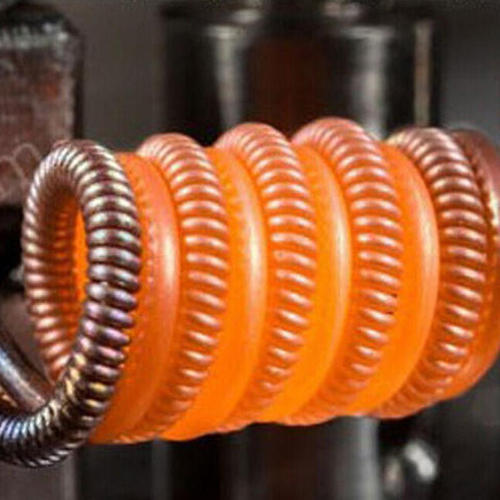

FeCrAl 0Cr25Al5 isitish elektr pechka simli isitish batareyasi

Isitish qarshiligi simining asosiy xususiyati

| Qotishma turi | Diametri (mm) | Qarshilik (mkm)(20°C) | Kuchlanish Kuch (N/mm²) | Uzayish (%) | Bukish Vaqtlar | Maks. Uzluksiz Xizmat Harorat (°C) | Ish hayoti (soat) |

| Cr20Ni80 | <0,50 | 1,09±0,05 | 850-950 | >20 | >9 | 1200 | > 20000 |

| 0,50-3,0 | 1,13±0,05 | 850-950 | >20 | >9 | 1200 | > 20000 | |

| >3,0 | 1,14±0,05 | 850-950 | >20 | >9 | 1200 | > 20000 | |

| Cr30Ni70 | <0,50 | 1,18±0,05 | 850-950 | >20 | >9 | 1250 | > 20000 |

| ≥0,50 | 1,20±0,05 | 850-950 | >20 | >9 | 1250 | > 20000 | |

| Cr15Ni60 | <0,50 | 1,12±0,05 | 850-950 | >20 | >9 | 1125 | > 20000 |

| ≥0,50 | 1,15±0,05 | 850-950 | >20 | >9 | 1125 | > 20000 | |

| Cr20Ni35 | <0,50 | 1,04±0,05 | 850-950 | >20 | >9 | 1100 | > 18000 |

| ≥0,50 | 1,06±0,05 | 850-950 | >20 | >9 | 1100 | > 18000 | |

| 1Cr13Al4 | 0,03-12,0 | 1,25±0,08 | 588-735 | >16 | >6 | 950 | > 10000 |

| 0Cr15Al5 | 1,25±0,08 | 588-735 | >16 | >6 | 1000 | > 10000 | |

| 0Cr25Al5 | 1,42±0,07 | 634-784 | >12 | >5 | 1300 | > 8000 | |

| 0Cr23Al5 | 1,35±0,06 | 634-784 | >12 | >5 | 1250 | > 8000 | |

| 0Cr21Al6 | 1,42±0,07 | 634-784 | >12 | >5 | 1300 | > 8000 | |

| 1Cr20Al3 | 1,23±0,06 | 634-784 | >12 | >5 | 1100 | > 8000 | |

| 0Cr21Al6Nb | 1,45±0,07 | 634-784 | >12 | >5 | 1350 | > 8000 | |

| 0Cr27Al7Mo2 | 0,03-12,0 | 1,53±0,07 | 686-784 | >12 | >5 | 1400 | > 8000 |

| NAME | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| ASOSIY KIMYOVIY | Cr | 12,0-15,0 | 23,0-26,0 | 19,0-22,0 | 22,5-24,5 | 18,0-21,0 | 21,0-23,0 | 26,5-27,8 |

| Al | 4,0-6,0 | 4,5-6,5 | 5,0-7,0 | 4,2-5,0 | 3,0-4,2 | 5,0-7,0 | 6,0-7,0 | |

| TARKIBI | Re | qulay | qulay | qulay | qulay | qulay | qulay | qulay |

| Fe | Dam olish | Dam olish | Dam olish | Dam olish | Dam olish | Dam olish | Dam olish | |

| Nb0.5 | Oy 1,8-2,2 | |||||||

| MAX HARORAT(oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| QARShILISH20oC (mŌ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Zichlik (g/sm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| ISILIK ALMASHI | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| RATE(KJ/m·h·oC) | ||||||||

| Kengayish tezligi (a×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| erish nuqtasi (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| kuchlanish kuchi (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| cho'zilish (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| maydonning o'zgarishi (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| egilish chastotasi (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| qattiqlik (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| mikrografik tuzilish | Ferrit | Ferrit | Ferrit | Ferrit | Ferrit | Ferrit | Ferrit | |

| magnit xususiyati | Magnit | Magnit | Magnit | Magnit | Magnit | Magnit | Magnit | |

| Diametri (mm) | Tolerantlik (mm) | Diametri (mm) | Tolerantlik (mm) |

| 0,03-0,05 | ±0,005 | >0,50-1,00 | ±0,02 |

| >0,05-0,10 | ±0,006 | >1.00-3.00 | ±0,03 |

| >0,10-0,20 | ±0,008 | >3.00-6.00 | ±0,04 |

| >0,20-0,30 | ±0,010 | >6.00-8.00 | ±0,05 |

| >0,30-0,50 | ±0,015 | >8.00-12.0 | ±0,4 |

| Qalinligi (mm) | Tolerantlik (mm) | Kengligi (mm) | Tolerantlik (mm) |

| 0,05-0,10 | ±0,010 | 5.00-10.0 | ±0,2 |

| >0,10-0,20 | ±0,015 | >10,0-20,0 | ±0,2 |

| >0,20-0,50 | ±0,020 | >20,0-30,0 | ±0,2 |

| >0,50-1,00 | ±0,030 | >30,0-50,0 | ±0,3 |

| >1,00-1,80 | ±0,040 | >50,0-90,0 | ±0,3 |

| >1,80-2,50 | ±0,050 | >90,0-120,0 | ±0,5 |

| >2,50-3,50 | ±0,060 | >120,0-250,0 | ±0,6 |

I Biz issiqlikka chidamli sim ishlab chiqaruvchimiz

FeCrAL sim, NiCr sim, CuNi sim:

II Asosiy afzallik va qo'llanilishi

A. Jismoniy parametr:

1) Sim diametri: 0,025 ~ 15 mm

2) Sof nikel yomonlashmasdan nisbatan yuqori haroratga bardosh berish qobiliyatiga ega. Maksimal ishlash

harorat taxminan 600 ° C

3) Nikel simi bitta simli yoki ko'p tarmoqli qurilishda mavjud. U zaxiradan yalang'och yoki izolyatsiyalangan holda etkazib beriladi

B. Xususiyatlari:

1) Ajoyib tekislik

2) Dog'larsiz bir xil va chiroyli sirt holati

3) Zo'r lasan hosil qilish qobiliyati

C. Asosiy ilovalar va umumiy maqsad:

1) Ushbu sim odatda tranzistor qopqoqlari, elektron quvurlar uchun anodlar uchun keng qo'llanilishi mumkin.

lampalar va sim-to'r uchun elektron komponentlar / o'tkazgich simlari. Turli xillar uchun chiziq shaklida ham ishlatiladi

ilovalar, shu jumladan Ni-Cd batareyalari

2) Shuningdek, kabellar, lampalar uchun qo'rg'oshin, elektron trubka tayanchlari, simli mato elektr ulash simlari uchun ishlatiladi.

haroratlar misga mos keladiganidan yuqori bo'lgan joylarda sim to'qish

3) Odatda qo'llanilishi quyidagilardan iborat: pechlar, plastmassa ekstruderlari, pechlar kabi isitish elementlari uchun tugatish.

Yoritish sanoatida filament tayanchlari va qo'rg'oshin simlari

Mahsulot toifalari

-

Telefon

-

Elektron pochta

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Yuqori